Office:888-440-2531

Sales:512-453-2533

Tech:512-406-1640

Industrial Communications

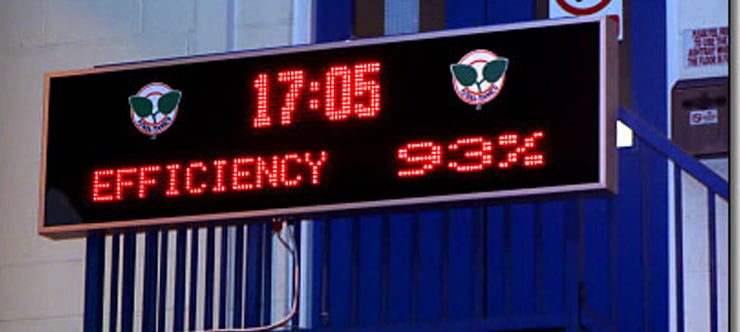

Lean Manufacturing

Promote the principles of Lean Manufacturing with the ability to instantaneously post production measurements on the shop floor. Put the right data in front of the right people to yield instant results. Significant increases in productivity can be realized by displaying production goals and actual results. Two-three line LED displays are perfect for each production line or cell whereas department wide or plant wide information is posted on large multi-line displays. Utilizing multi-color LED displays can greatly improve the readability of large size multi-line displays by displaying positive information in Green, negative in RED and neutral in AMBER.

Safety Messages

Post safety messages that can be seen and read by employees. Build employee interest in plant safety programs and reduce lost work days by communicating through attention-getting LED safety messages. Increase employee participation in company safety meetings by frequently announcing scheduled meetings.

Warehouse Management

Quickly and efficiently direct warehouse shipping and receiving activities. Use outdoor LED displays over dock doors to direct delivery trucks to the correct loading docks. Use indoor displays to direct forklift operators to the appropriate loading dock to receive and load products. Five critical areas where LED displays can be used are inventory management, storage, receiving, picking and shipping.

Production Employee Communications

Place LED displays and LCD/PLASMA monitors in high traffic areas such as walkways, break rooms and lunch rooms to communicate information from the HR, safety, production and quality control departments.

Alarm alerts Use LED displays to identify the location and nature of a problem and to direct the appropriate personnel to it. The urgency of problems can be identified by color codes and strobe lights. Strategically placed LED displays and LCD/PLASMA monitors can be seen from anywhere in the production facility.